I made one more “confidence layup”. This one I did according to the instructions. When I made the first one, I had misread the instructions and used polyvinyl foam instead of polyurethane. The PV foam is a lot stronger and is used in structural applications on the airplane, so this should have made the piece stronger. What I didn’t notice until recently was that the instructions also say to use 0.5″ thick foam, and the PV foam is 0.75″. Since the strength of a beam depends strongly on its height (I seem to remember going as h^2 from the days of structural mechanics many years ago) that would also make the piece stronger. So no wonder it could take Greg’s weight…

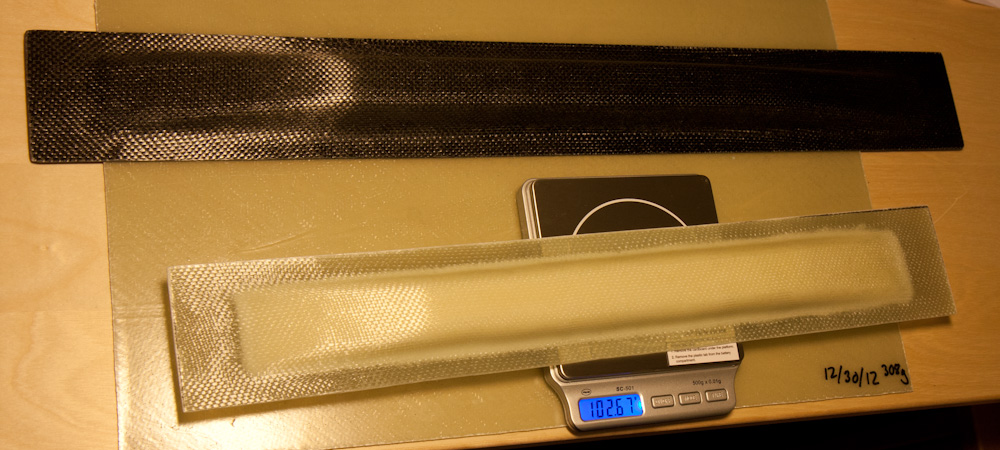

I figured I should try making one out of polyurethane just to try working with it. Wow. I knew polyurethane is a lot more brittle than the other foams (on the airplane it’s used in non-structural applications where ease of shaping is important, like the nose) but actually seeing it in action was an eye-opener. It basically turns to dust if you even look at it sharply. This made making the “beam shape” of the confidence layup a piece of cake. (The PV foam was surprisingly hard to cut and sand.) Here’s how it came out, in comparison with the carbon fiber piece:

The polyurethane piece on the scale, weighing in at 103g. Note the as-asked for 16″ length compared to the oversized carbon fiber one.

I was interested to see if this piece would crack right away when subjected to the strength test. Nope, it hold up to at least my 150lb without any problem.

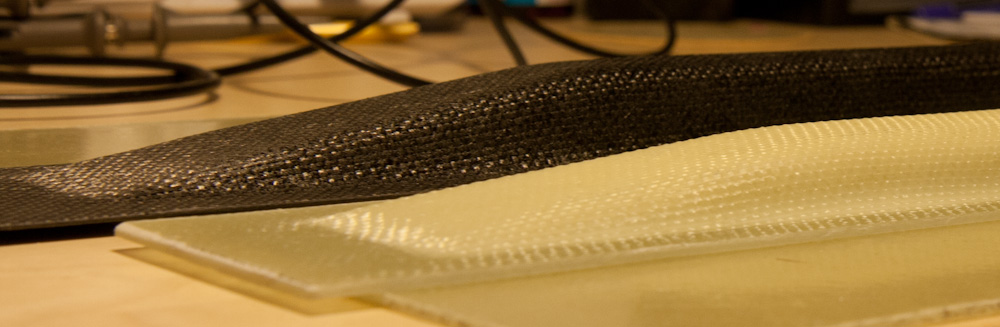

From this view, the the new piece’s 0.5″ height compared to the 0.75″ of the carbon fiber one is apparent.

I’m currently working on the third practice layup — the book end. More on that shortly.