When I bought my supplies from Aircraft Spruce with the 20% discount from the workshop, I threw in a yard each of carbon fiber BID and UNI just to try working with it. I made another “confidence layup”, this time out of carbon fiber.

Since i had obvious air gaps at the inside corner when I didn’t make a radius with micro on the last one, I filled all the inside corners with dry micro. This time I tried putting the micro in a ziploc bag and cut a corner off. That way you can squeeze out a very clean bead of micro and then just shape the radius with the tongue depressor. It worked great, no micro on the fabric surfaces at all!

The carbon fibers are noticeably stiffer than the glass ones. The fabric I used had roughly the same strength as the normal 7725 fiberglass BID, but was quite stiff. I was a bit worried about whether it would conform to the corners, but that turned out to not be a problem.

Another issue with doing open layups with CF is that, since it’s black, you obviously can’t see through the layup. This means you’re basically working blind when it comes to making sure you don’t have any air bubbles trapped. This is one of the major reasons that people recommend using vacuum bagging when working with carbon fiber.

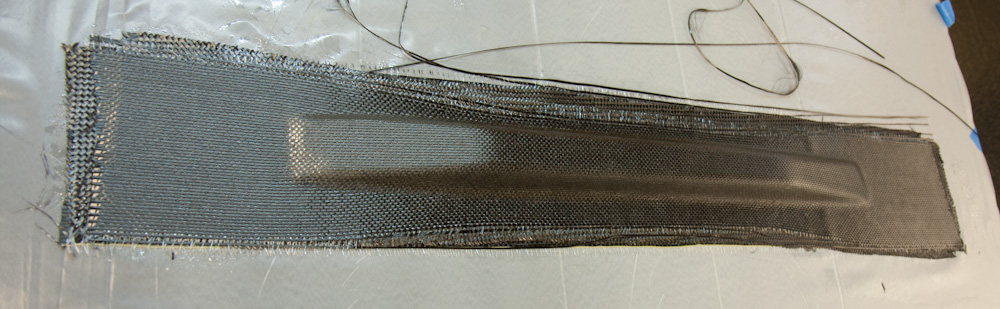

After knife trim, the piece came out like this. Looks quite high-tech… The weight is 70g, compared to the 112g that the fiberglass piece weighed.

Now, the weight difference isn’t really apples to apples. For a start, this piece is 2″ longer (1/8) than the glass one. If I had made it the same length, it would have weighed about 61g. More importantly, this piece is less strong… I used only about half as much weight of fabric, and contrary to what you might think, carbon fiber isn’t really that much more strong than fiberglass. It depends on the quantity you are interested in.

Some thoughts about carbon fiber vs fiberglass

While the general impression is that carbon fiber is space-age awesome and must be lighter, stronger, and better than fiberglass in every sense, when you actually start looking into it the truth is a bit surprising.

The 7725 BID fiberglass cloth I have has a breaking strength of 400 lb force per inch and weighs 8.6 oz/yd^2. If you divide out the weight to get the strength per weight, you get 46 lb yd^2/(in*oz). The units are funny but it means we get 54 lb/in strength per ounce weight of fabric.

If we do the same with the 282 BID carbon fiber fabric, it has a breaking strength of 300 lbf/in and weighs 5.8 oz/yd^2. If we do the same exercise, we get 51 lb yf^2/(in*oz). So contrary to what you might think, the breaking strength of carbon fiber is only about 10% higher than for an equivalent weight fiberglass fabric!

On price, however, there is no contest. If we do the same exercise but instead of weight use price, fiberglass gives you 54 lb yd^2/(in*$) against carbon fiber’s 14. So if you need a certain strength, it’ll cost you about 4 times more to use carbon fiber compared to fiberglass.

So what is the advantage of CF? The one place where the materials really differ is in stiffness. The Young’s modulus, the measure of how much force it takes to stretch the material, for carbon fiber is about 4.75 times higher than for glass. If we now divide out the density again, we get the specific modulus, which is a measure of how much force it takes to stretch a certain weight of the material. Because glass is about 1.4 times heavier than carbon, this quantity ends up being 6.7 times higher for carbon fiber than for fiberglass.

What does this mean? Suppose you build a two identical parts, one using fiberglass and the other using the same weight of carbon fiber. It would seem they would have about the same breaking strength, but the CF part would flex much less than the glass one. Less flex sounds good, right?

Well, not really. The fact that the glass flexes more is actually a strength advantage, because it allows the material to deform and spread the load over a larger area. In contrast, because the CF is so stiff, the forces can become much more localized. And since the breaking strength of the material used is about the same, this means that it’s much more important that the CF part be designed to take exactly the forces it will be exposed to, and there’s much less margin for error. Once you reach the breaking strength of the material at one point, the fibers will rupture and at that point the structure will likely come apart.

This effect is demonstrated by the difference between tearing a sheet of paper (which is very stiff) and tearing a sheet of rubber. The paper fibers will rupture at the edge and the rip will quickly propagate. The rubber, however, will just stretch and distribute the load over the entire sheet, and it ends up being a lot harder to rip. If you google for “broken carbon fiber” you’ll find tons of pictures of bicycle parts where something has come apart catastrophically. This is what I’m talking about. A less stiff piece would likely not have done that.

So it seems the relative advantage of using CF as a composite material depends on the requirements. If you need a stiff structure, it’s much more weight-effective than fiberglass. If you can tolerate flexion, however, and are concerned about ultimate breaking strength, it seems there’s not much weight gain to be had (and many $$$ to be lost) by using CF. Plus, design becomes much more critical. An airplane doesn’t seem like an application that’s flexion limited, it’s not really a big deal if the wings bend under load. So, it seems fiberglass is a good material for that application. I guess the possible exception is if you’re worried about flutter, then the increased stiffness might be desirable.

Interesting.

Interesting comparison Patrick. I am looking at a project and was trying to decide between glass and fiber. Seems it does not make sense to incur the additional cost.