I finally got a rear stand for the NC30 so I could take a look at the rear wheel. Since it has a single-sided swingarm, you need a stand that has a big fat pin that’s inserted into the rear hub, and it turns out those stands are a) much more expensive than normal two-sided rear stands and b) the diameter pin needed for the NC30 is of course different from almost every other bike. It is however the same as for the RC30, which was officially imported in a few precious units in 1990 and hence (sometimes) shows up in US fitment charts, so finally I found an online store that had the correct diameter pin.

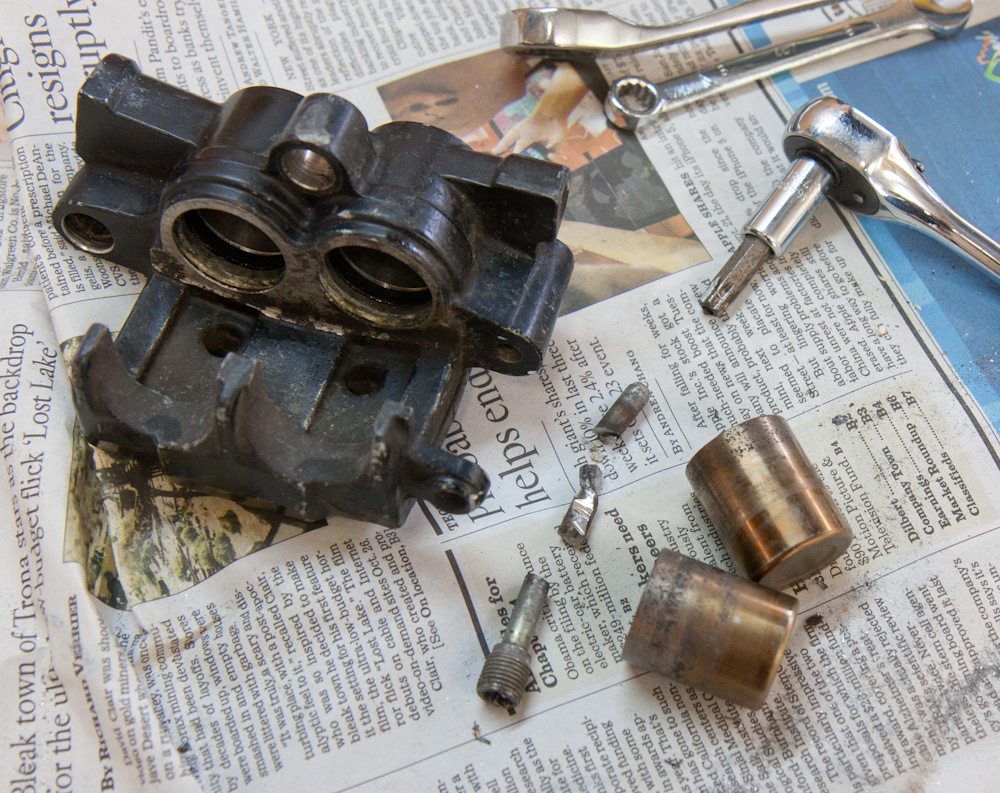

Anyway, The first thing I did was take off the rear brake, which hardly worked. I figured stuff would be all corroded and gunked up, and boy was I right. The pistons were practically seized in the bores. Moreover, the pin that holds the brake pads in the caliper was stuck fast. It takes a 6mm Allen socket, and even after soaking PB Blaster on the screw I promptly rounded it. I resorted to cutting the pin with a Dremel so I could take the pads out. Then I ground the back of the pin flat so I could fit a wrench on that side, drilled out the front side and hammered a Torx bit into the screw, heated the caliper with a propane torch, and tried to turn the screw from both sides. Eventually it popped loose, but I had to upgrade to a longer socket handle that the one in the picture.

It turned out I already had the seals, because I got a set of seals for the front calipers but never ended up taking them apart. (Maybe that was a mistake, but the front brakes work fine.) The smaller front piston is the same as the rear one, so they take the same seals. The pistons were pretty badly corroded, so I ordered new ones. And I obviously needed a new pin…

I soaked the calipers in ethanol, which dissolved a lot of gunk but did not get rid of the hard corrosion in the groves for the seals. Eventually I had to do some careful Dremeling, first with the nylon brush and then the brass brush, to get them clean.

The inside of the caliper bores. The seals were stuck in place due to corrosion. You can see how the left seal sticks up from all the corrosion under it, thus seizing the piston in the bore.

When I put it all back together, the new piston slid way easier than the old ones. I added a generous amount of antiseize to the new retaining pin, which hopefully will prevent the same thing from happening again. The caliper sliding pins were actually in pretty good shape, so I just cleaned those up and added new grease. Bleeding the long line from the pedal wasn’t even as bad as I feared.

I’ve only taken it for one short test ride (with the new clutch) and the rear brake still sucks. I’ll give it a while to wear the pads in to the rotor before I render a verdict. As of now, I probably can’t lock the rear wheel even if I stand on the brake pedal. Maybe it’s safer that way…