Both the NC23 and the NC30 are known for having weak regulator/rectifiers. Mine seemed to work, though I’d definitely noticed a very distinct brightening and dimming of the lights when revving the engine. Since I have enough things to fix on these bikes, I didn’t exactly go looking for more. Then I started digging into the electrical system on the NC30…

It started with the headlights. Since I want to replace the Tyga Thai-special headlight with stock ones to have any hope of passing the Hawaii safety inspection, I was looking for the second H4 connector. The Tyga headlight only uses one, but I figured the other one would be tucked back there somewhere. However, I couldn’t find it. Eventually, I took the entire instrument cluster off, and after unwinding some electrical tape I found a stub of three wires. Apparently it was just too much weight to keep an unused H4 connector around, so naturally you just snip that off the impossible-to-replace wiring loom…

Whatever, it’s no big deal to splice some wire on there and add another connector. But I got tired of getting completely filthy with grime whenever touching anything on the bike so I decided to take the fairings off and pull it out into the driveway for a little decontamination. This rapidly led to some unpleasant discoveries.

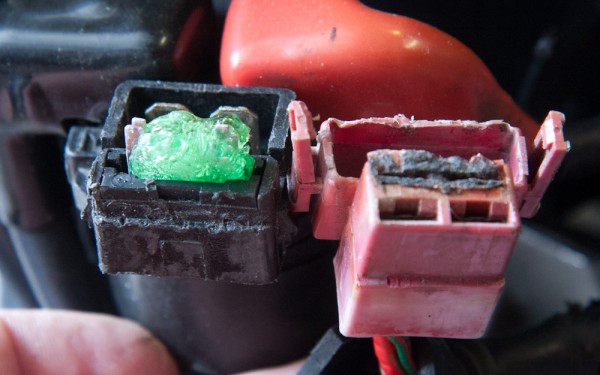

First was the fact that I had a hard time getting the connector to the starter relay / master fuse off. After some violent wiggling, I was presented with this:

Apparently the connections to either the fuse or the connectors (the two blackened connectors are the supply from the alternator and the connection to the rest of the bike) had deteriorated enough that it totally melted itself. These connectors carry the full charge current and current draw of the bike, and they aren’t sealed, so I guess 20 years worth of corrosion is enough to do that.

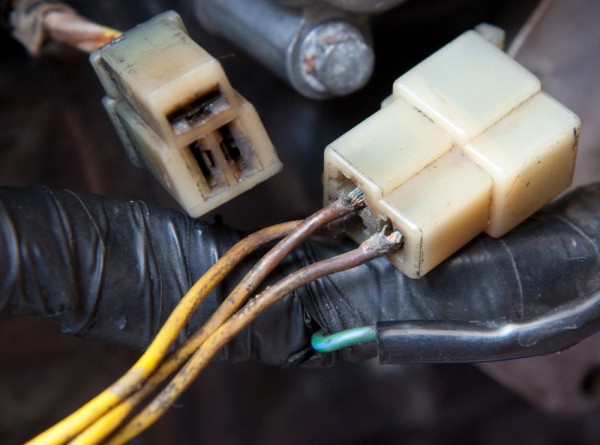

Continuing around the right side of the bike, I came to the collection of connectors on the right side of the engine:

One of these connectors are where the wires from the alternator join the main loom on their way to the regulator. These carry the charging current from the alternator and are also not sealed. The connector hadn’t melted, but the insulation had charred and even bubbled from overheating, so it’s clear the connection here isn’t good either.

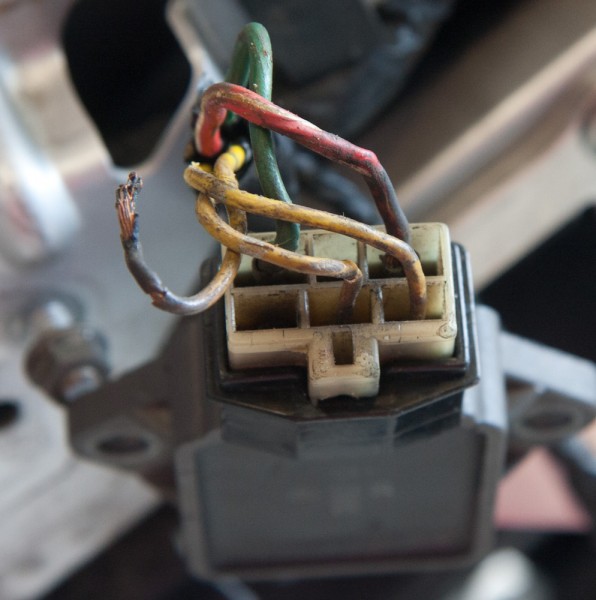

This led me to the other end of those wires, at the regulator/rectifier. This connector I couldn’t even get off, but that wasn’t necessary to see how it’s doing; the alternator wires came apart as I tried to get the connector off.

Before I tried getting that connector off, I plugged everything back in and started it. The alternator and rectifier connectors got uncomfortably hot pretty much right away. In case there wasn’t enough motivation before, having hot wires definitely puts me out of my comfort zone…

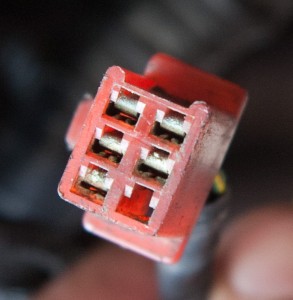

The damage isn’t confined to the high-current connectors. The connector to the right handlebar switchgear was also badly corroded:

The connector to the right handlebar switches. It’s a bit hard to tell in the picture, but the terminals are covered with white corrosion.

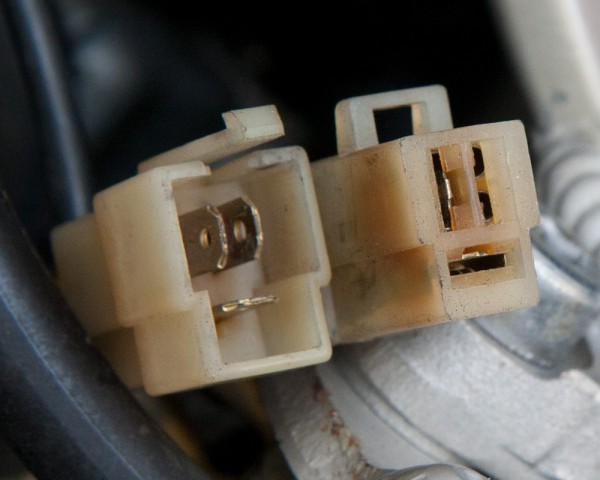

After this disappointing discovery, I figured I should see how the NC23 is doing. The answer is: better, but not good:

The alternator connection on the NC23. No melted insulation here, but the connector definitely looks distressed.

The rectifier connector on the NC23. This one’s also darkened from heat, even if the wires haven’t melted yet.

The NC23 appears to be in no immediate danger of catching fire, but the connectors definitely show signs of overheating. I suppose it would be better to fix this problem before it gets to the NC30’s state.

The problem seems to be that the unsealed connectors used by Honda, with maybe marginal current capacity to begin with, can’t survive being exposed to the elements for decades without corroding and then burning up. Maybe these connectors were state of the art in 1990, but today you can easily find sealed, high-current connectors. It seems this part of the bikes is ripe for an upgrade.

Rectifier technology also has improved over the last 20-25 years. Modern MOSFET-based rectifiers are more efficient, run cooler, and have better regulation than the units mounted on these bikes. If I’m going to start replacing things, it makes sense to put in a modern unit instead of waiting until these go out and possibly take the ECU with them. This post goes into a lot of detail about rectifier upgrades. The only problem is that the FH020 unit that is easy to find for upgrades is humongously large compared to the original unit and with 50A capacity it’s clearly overkill. The FH008 one that was used on CBR600’s around 2005 has the same hole spacing, 60mm, as the stock units on both the NC23 and NC30, and with 35A capacity it should be fully sufficient for our needs. That one is harder to find, though.

So, I’ve started gathering a shopping list of Metri-Pack connectors, automotive-quality wire, and scouring the web for rectifiers. This will be redone correctly , so there’s no chance of this problem recurring. I’ll post an update when things start happening.

Pingback: NC30 alternator rewire #1 | Patrik's projects