In the last post, I described the basic idea of the dehumidified filament storage box. I don’t have a lot of time to work on it, so progress is slow, but I’ve done a few layups.

The layup on the inside of the back section of the box. This side has these aluminum hard points, that will be drilled and threaded to hold the hot plate.

The back side is made from 2″ foam to give good insulation against the hot plate and maximum rigidity. That part has been glassed on both sides. I floxed 4 aluminum hard points on the inside so the heater plate can be attached.

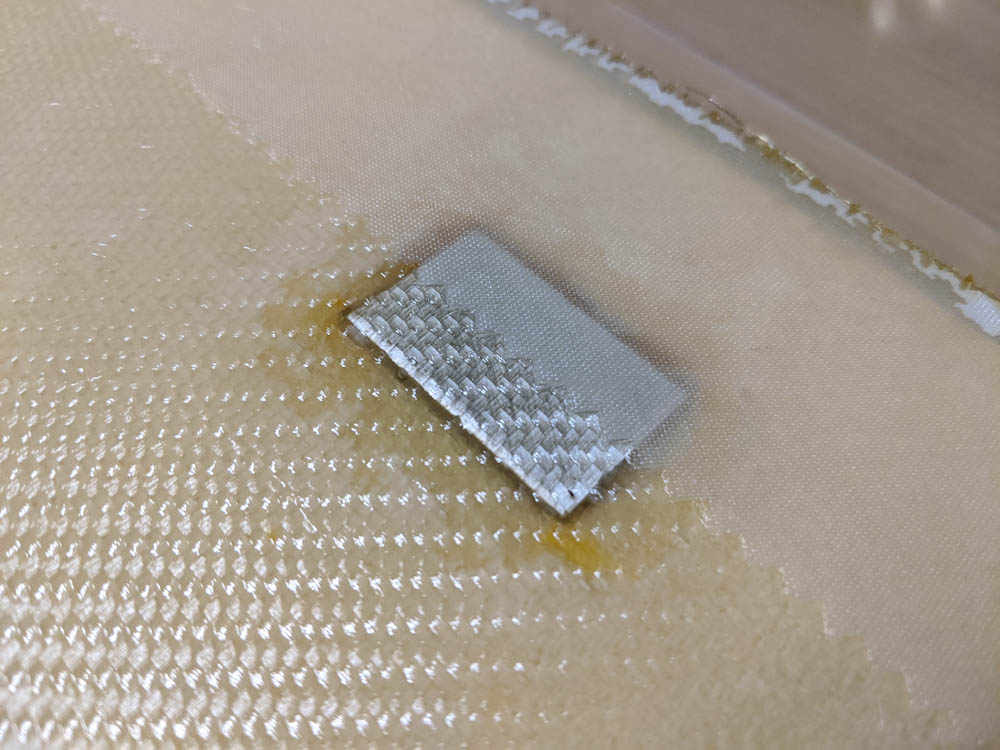

A closeup of one of the aluminum hardpoints. They’re made of 1/4″ 6061 floxed in place under the glass.

The right side of the box, where the fan and the cold plate for the dehumidifier is mounted, is partly completed.

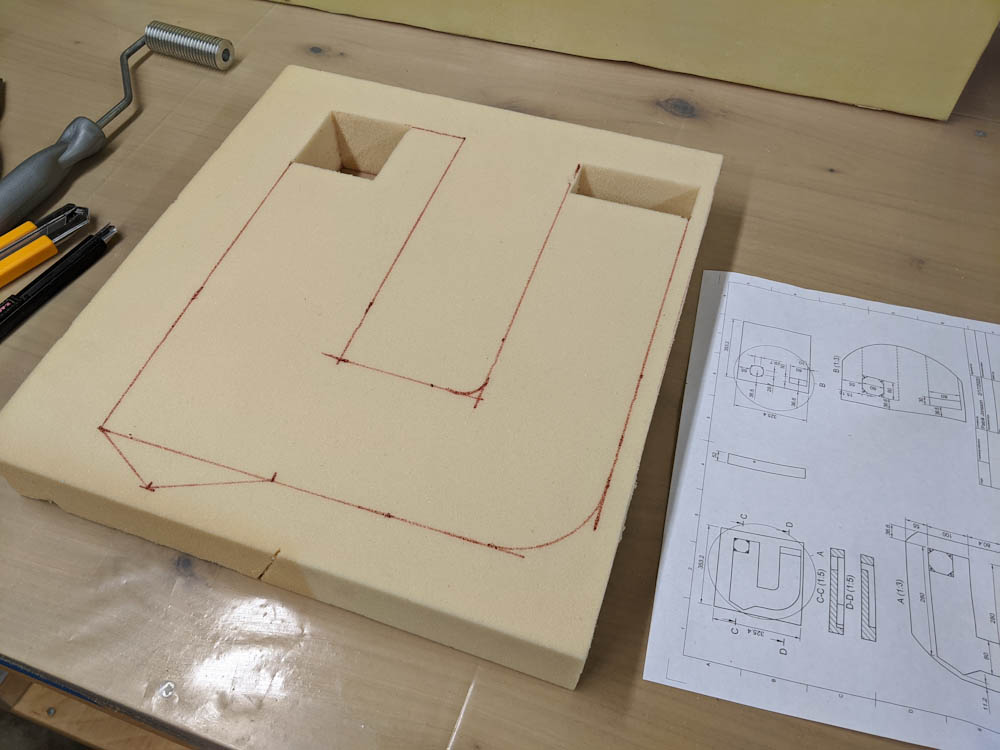

The right side of the box, with an outline of the dehumidification passage. The fan sits in the upper left, then the cold plate will go below it, mounted on the top. The passage has a bottom collection point where the condensate will gather and run out, and then the air circulates back up and re-enters the box through the hole in the upper right.

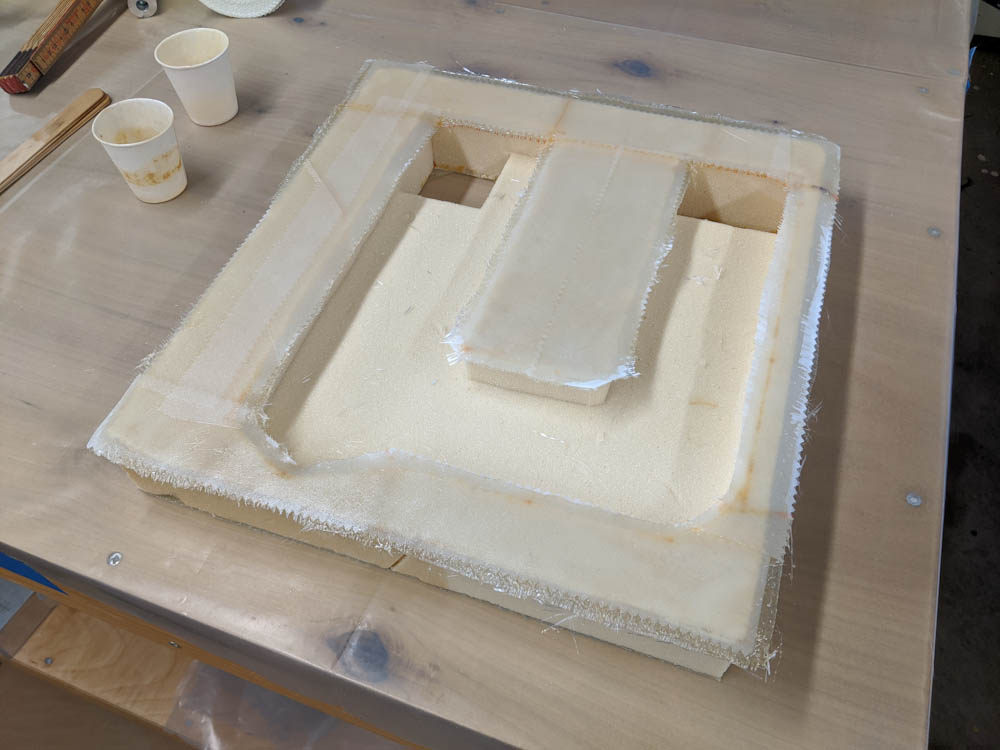

Here the foam has been routed out for the air passage, and the surface glassed. The passage itself will be glassed separately once the surface has cured. There are a lot of corners here so it will be pretty tedious to do.

I started using West System epoxy, which is what I’ve used exclusively for glass work since I bought it back in 2012. However, since the inside of this box will be quite warm, well above the heat deflection temperature of the West System, I decided it would be a good idea to pull out the Pro-Set that I got way back before we moved from L.A. If post-cured, it has a much higher heat deflection temperature up towards 80-100C, so it seems a better choice. It’s not like I’m using it for anything else, anyway.

I was a little bit worried that it would no longer be good, since it’s specified with a shelf life of 2 years, but I mixed a test batch and it cured fine. The hardener has turned very brown, much more so than the West hardener, even though it’s been in sealed containers, but it doesn’t seem to affect the cure.

However, I have been getting a sticky, oil-like layer on top of the cured expoxy, especially the stuff that remains in the cup. I assume this is what’s known as “amine blush”, a byproduct of the hardener reacting with moisture. I’ve never noticed it with West System, but the Pro-Set instructions warn that it’s possible. The high humidity here (I’m working in the garage, too) probably doesn’t help. Maybe I should be doing the layups in the dehumidified room…

Pingback: Filament storage part 3 – Patrik's projects