As you may remember, my 3D printer is mostly used with Nylon or polycarbonate filaments, since those are strong and works to high temperatures. Unfortunately they’re also very hygroscopic, so they absorb moisture from the air (which we have a lot of here) and then you can’t really print with them without getting blobs and oozing everywhere. You can literally see steam coming out of the nozzle when printing if the filament’s been sitting out.

To fix this you have to dry it before printing, and then keep it dry. I’ve been doing this by keeping the filaments in the oven at ~80C for a day and then storing them in air-tight tupperwares along with boxes of dessicant. This makes it doable, but isn’t really cutting it in the long run.

First, drying a full spool doesn’t actually dry it all, the inner part must not get enough airflow so even after a day it’s not sufficiently dry to print. Since I often print large objects that use the better part of an entire spool, this means that at some point during the print things will start going south as you get into the un-dried part of the filament.

Second, the “air-tight” containers aren’t, and even if they were you have to open them and put the spool into the little box on the printer I feed it from. This means the dessicants get saturated, even though I have about a pound in there. You can dry them, but that gets old, too.

The net effect of this is that I basically don’t print stuff unless I have a big project that warrants baking filaments and dessicants. These days time is a sparse commodity so streamlining this would do wonders for being able to use the printer as an everyday tool.

So here’s the plan:

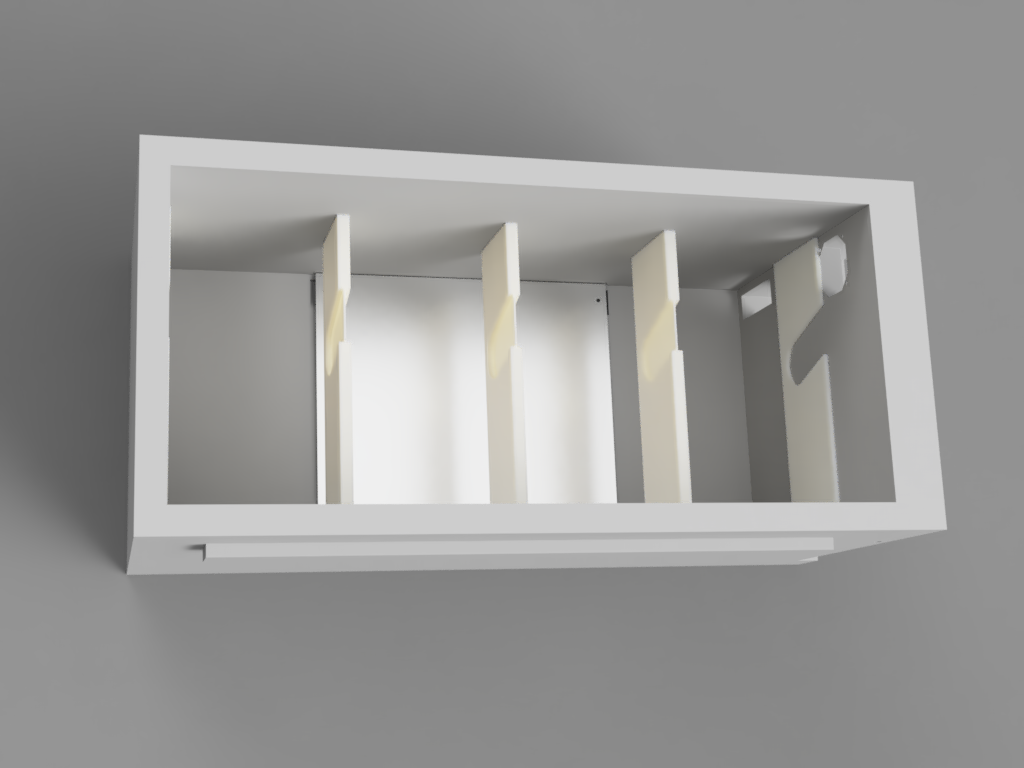

I’m going to build a large, insulated box where I can store several spools of the filaments I use most often. This box will have a heater that can heat the entire box to 80C to bake the moisture out of the filaments. It will also have a dehumidifier, essentially a cold plate where the moisture in the air will condense and then leave the box. The box will have outlets with teflon tubing where the filament will feed directly into the printer. The tubing for filaments that aren’t used can be stuck back into the box to seal those holes. This way, filaments will be continuously baked and kept dry.

A rendering of the filament storage box in Fusion 360. The square in the back is the heating plate, the holes on the right for the dehumidifier.

For making the box, I will make use of some of the foam and fiberglass I have for the on-indefinite-hold Long-Ez build. The heater will be the old heater plate for the 3D printer, which is capable for 360W at 24V. The dehumidifier will re-use the thermo-electric cooler from the long-defunct Wine fridge (see the first ever post on this blog!)

An internal fan will circulate the air internally, and on one side of the box another fan will blow air into a passage that contains the cold sink of the thermoelectric cooler and then comes back out into the box.

Finding fans that are OK with being put into an 80C environment is a bit tricky but Mouser has a few. The humidity and temperature in the box and after the cold plate will be monitored with the same kind of sensors that I use for the weather station. Controlling it all will be, of course, an Arduino.

Both software and hardware-wise, I already have most of what will be needed for this project, since the functionality is some mix of the weather station and the epoxy hot box. I did need to buy the fans and a power supply (for the 12V thermoelectric cooler and fans, for the 24V I’m reusing the one from the 3d printer.)

Sorry for this wall of text, but I wanted to give an outline of what I’m going to do. I’ve started making some parts, so hopefully I can give a first progress update soon.

Pingback: Filament storage part 2 – Patrik's projects